3D Printing and CNC Machining

CeeD Awards

The techniques and technologies below were used to deliver an award-winning 3D printing and CNC machining project for the 2020 CeeD Awards:

Techniques

- Metal 3D Printing

- 5 Axis CNC Precision Machining

- Modelmaking

- Spray-painting

Technology

- M2 Concept Laser Metal 3D Printer

- Promac 5 Axis CNC Machine

The Client

CeeD is a growing community of businesses and academics who have come together to share their talent, expertise, experience and resources in the pursuit of operational excellence. Together, CeeD focusses on areas its members specifically need to improve and helps them achieve greater prosperity by solving the real operational issues they all face.

The Challenge

For a client like CeeD – who’s whole reason for existing is to help achieve excellence in every area possible – any project was going to be demanding. But we also knew that the 2019 awards had set a high bar.

However, this year CeeD wanted to incorporate additive manufacturing or 3D printing into their award-winning members’ trophies for 2020. With that in mind, they reached out to CA Models to deliver a truly award-worthy 3D printed design they would be proud to give out on the night.

The Solution

Initial stages of the project included some very productive meetings with the CeeD team – particularly Gillian Wishart (Business Development Manager) and Joe Pacitti (Managing Director). They added great ideas and inspiration to the brief, helping our design team provide an initial render that started us on the road to the final design.

Ultimately, the winning award design was both 3D printed and CNC machined – exhibiting a great blend of our available in-house technology, materials and finishing:

Base – CNC Precision Machining

The base for the CeeD award was precision machined in aluminium using our Promac 5 Axis CNC machine. This gave each trophy a robust, beautifully finished foundation – ensuring a solid, high-quality weighted feel in the hands of the award winners.

Lettering – 3D Printing and CNC Precision Machining

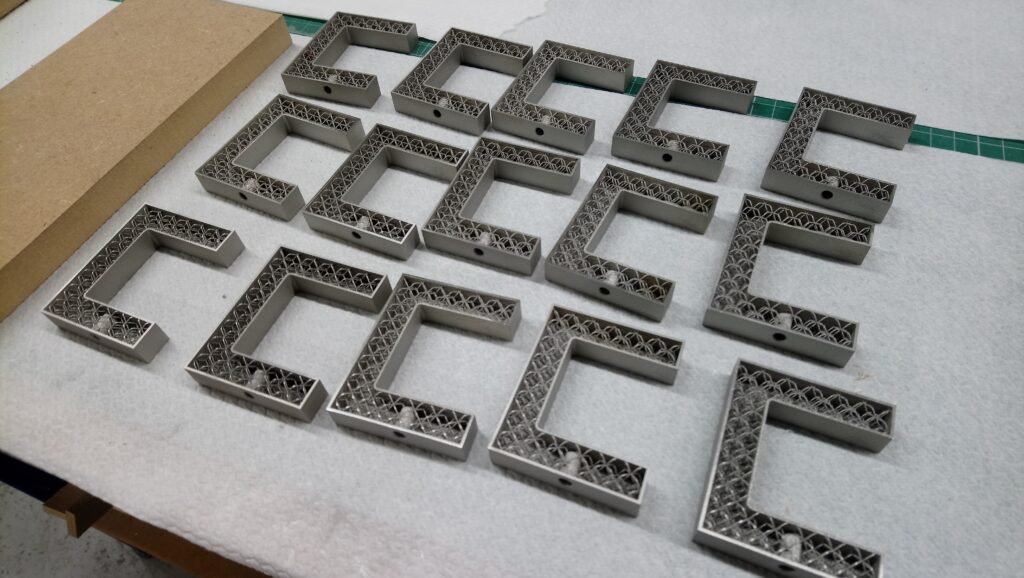

The main body of the trophy consisted of the ‘CEED’ lettering, arranged in an off-set, stacked block design. Like the base, the E, E, and D were made from aluminium and utilised precision CNC machining in our Promac 5 Axis CNC machine.

However, the letter C was created via metal 3D printing. And for this element we used a stainless-steel powder material, printed on our M2 Concept Laser machine, to beautifully complement the solid aluminium of the EED.

Finishing – Modelmaking & Spray Painting

After manufacturing each element, the awards were intricately assembled by our model making team in our on-site workshop – ready for their finishing touches in our spray-painting department.

CeeD opted for a striking metallic blue for the lettering to tie in with their logo. The base was then finished in metallic silver and gunmetal, complementing the bold metallic blue of the letters.

The Result

The finished trophy was stunning – a combination of 3D printing, CNC machining and expert finishing that reflected the excellence CeeD strives for every day. We were delighted for all the award-winners to take home a piece of CA Models craftsmanship, as was our client:

“CA Models were a dream to work with – the professionalism and quality of their work was second to none. This was surpassed by the enthusiasm and guidance they provided to us – a reflection of a truly customer focused business with great people too.”

Joe Pacitti, CeeD Managing Directory

And we were even more delighted to be an award-winning company ourselves. CA Models received the CeeD 2020 Peer Recognition award, presented by Shereen Nanjiani – pictured above with Managing Director Clark Campbell, Gregory Campbell and Jamie Campbell.

That’s what we call a win-win project!