Delivering Cellular Level Precision via

Metal 3D Printing

The techniques and technologies below were used for 3D printing a complex part that demanded ‘cellular level’ precision for Diamond Light Source Ltd:

Techniques

- Metal 3D Printing

- 5 Axis CNC Precision Machining

- Hand-finishing & Polishing

- Spray-painting

Technology

- SLM 500HL Metal Additive System

- Promac 5 Axis CNC Machine

The Client

Diamond Light Source is the UK’s national synchrotron – working like a giant microscope, it harnesses the power of electrons to produce bright light that scientists can use to study anything from fossils to jet engines to viruses and vaccines. As one of the most advanced scientific facilities in the world, Diamond’s pioneering capabilities are helping to keep the UK at the forefront of scientific research.

The Challenge

In a nutshell, to successfully 3D-print the sample vessel for the national synchrotron’s new ‘VMXm beamline endstation’, using aluminium Direct Metal Laser Sintering. If that sounds complicated, it’s because it was. And until they reached out to CA Models, our client was struggling to find someone to who would even take the project on.

Diamond Light Source Ltd were designing a specialist part that would enable the powerful process of studying objects at a cellular level! This part would be used to help hold the sample particles in a high-vacuum of 10-6mbar – a condition that is essential to the process.

It was clear from the start this ‘vacuum vessel’ was going to be of highly complex design. And as the design progressed, it became clear that using conventional manufacturing and fabrication techniques would not work. This led to Diamond designing the vessel to be 3D printed in aluminium using DMLS (Direct Metal Laser Sintering). So far so good…

3D printing would allow Diamond greater freedom of design and to build in many features that would otherwise require a number of different components. The layout was improved and saved on space that was in very short supply. However, the finalised design was not yet optimised for the DMLS process.

Diamond went in search of 3D printing experts who could realise their design vision, by optimising and delivering the part as needed via Aluminium DMLS.

The Solution

When tendering the project, Diamond Light Source were met with responses ranging from claims the design was too complex and declines to quote, to those who wanted to unpick all their hard work with massive design changes and a hefty quote to do so.

That was, until they reached out to CA Models.

The Quote – Almost Too Good to be Believed

With the range of technology at CA Models, and the skills and experience of our team, we were able to provide a highly competitive quote with total confidence. And crucially, with no changes to Diamond’s elegant and space efficient design.

In fact, after so many negative responses, Diamond’s lead Mechanical Engineer thought our offer was too good to be true when he received it.

“On first contact they quickly supplied us with a competitive price with no re-design conditions attached. Being wary of such a good offer I spoke with the managing director Clark Campbell – a very enthusiastic man confident of his company’s abilities and up for the challenge. He showed me some of the work they had previously produced and that was enough to place the order.”

The Build – Metal 3D Printing, CNC Machining, Hand-finishing

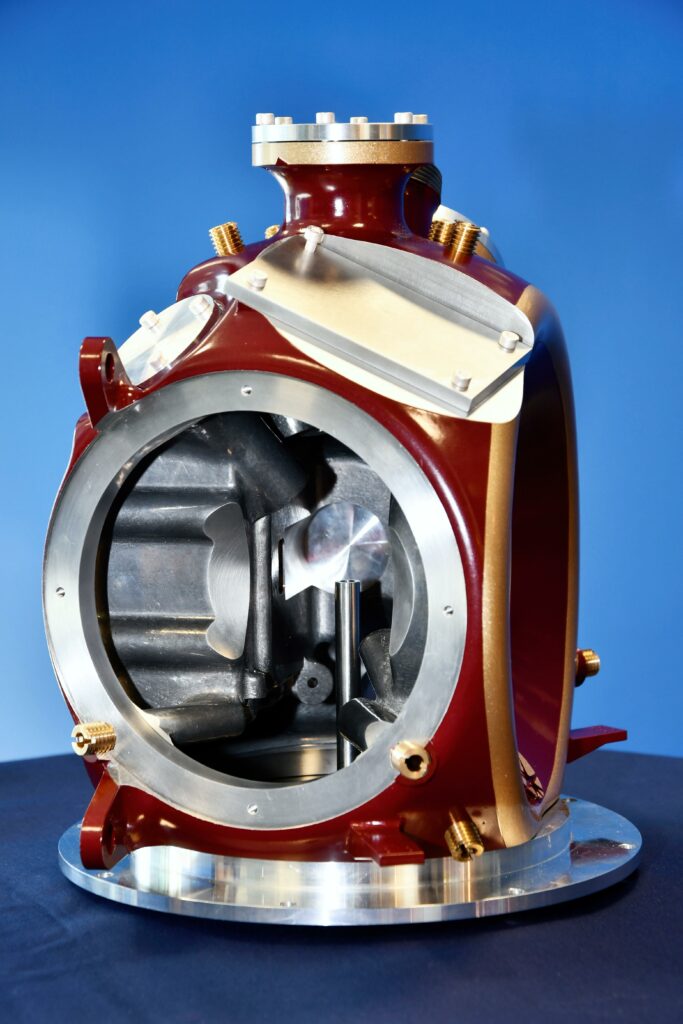

Though extremely challenging, we knew the vessel would be the ideal showcase for our quad laser SLM 500HL metal additive manufacturing machine. It boasted 8x Equipment ports, 5x Camera / Inspection ports, 4x Laser sensor ports, 3mm X-Ray input hole, and a large output window cone.

After interrogating the complex CAD file and associated machining PDF details, our engineers formed the optimal build orientation and support strategy for the print. Once everything was ready, this incredible part took two and a half days to complete – measuring 262 mm x 300 mm x 200 mm and weighing in at 4kg.

Finishing – CNC Machining, Hand-finishing, Spray-painting

We then removed the build structure and carefully hand finished, polished, inspected, and CNC machined the vessel to its perfect finished state. Well, almost…

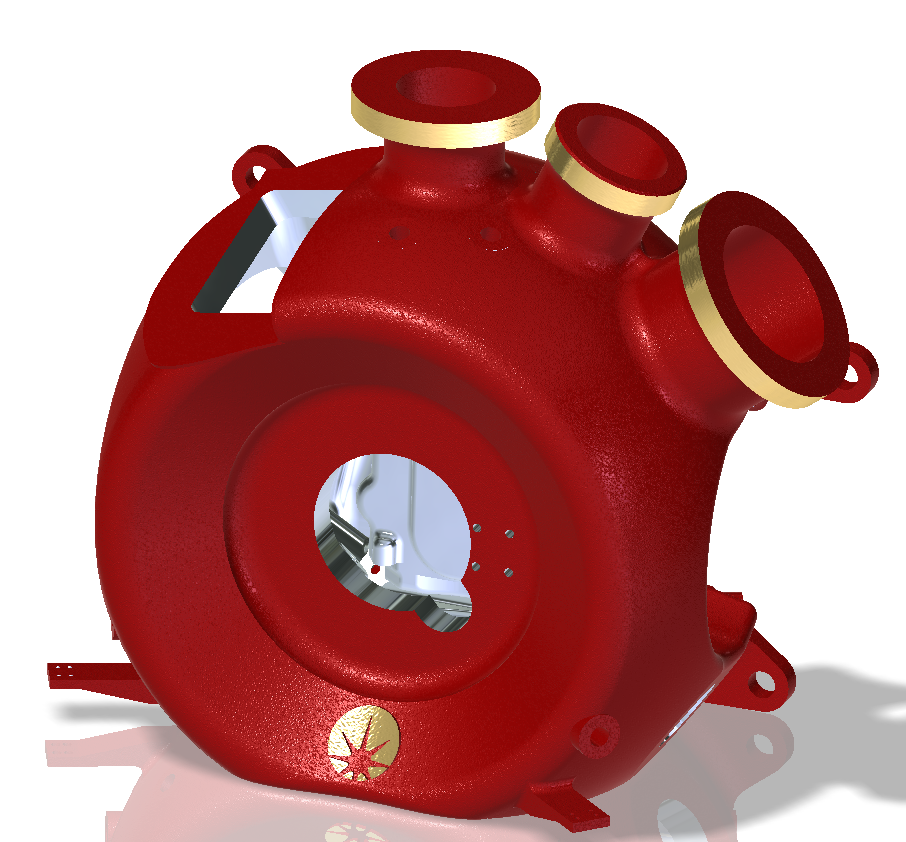

The real finishing touch was still to come with a trip to our in-house spray-painting department. And as a fun final twist to this challenging build, the principal scientist requested the vessel be painted in Ironman colours!

The Result

The finished vessel was tested and used to prototype other parts of Diamond’s beamline for conducting cellular level examination. It was then installed on the final ‘beamline’ which went into operation in early 2018.

There is nothing we love more at CA Models that rising to the challenge of something that has never been done before to solve a problem for our clients. And you don’t need a high-powered microscope to see this project was a success for all involved.